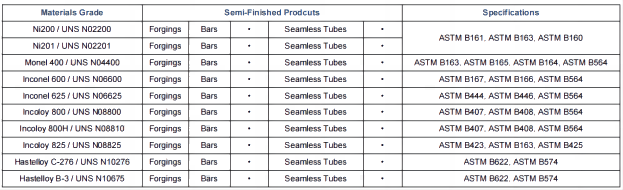

Alloy C276 • UNS N10276

The Hastelloy C276 Pipe is covered by 2 specifications i.e. ASTM B622 as well as ASTM B619. Typically the ASTM B622 Pipe is constructed in a seamless manner, whereas the construction of the ASTM B619 Pipe is welded. Amongst all the Hastelloy variations the C276 Hastelloy Pipe is the most popular one.

The low content of carbon in the 2.4819 Alloy C276 Pipe is what minimizes carbide precipitation. Carbide precipitation is a phenomenon that occurs during welding of various alloy grades. A lower carbon based alloy such as the ASTM B619 UNS N10276 2.4819 Pipe is used in several applications which have the need to maintain its corrosion resistance properties in as-welded structures. This specified nickel Hastelloy C276 Seamless Pipe is also resistant to the formation of grain boundary precipitates, especially its occurrence in the weld heat-affected zone. Thus the Hastelloy C276 Welded Pipe is well suited to be used in chemical process application in an as-welded condition. By adding tungsten in the ASTM B622 UNS N10276 Alloy C276 Pipe, its corrosion resistance properties become superior. For example, the ASTM B622 UNS N10276 Pipe exhibits excellent resistance to pitting and crevice corrosion in both reducing and oxidizing environments.

Alloy 625 • UNS N06625

Nickel based Inconel 625 Tube covered by the ASTM B444 takes into consideration cold worked seamless construction tubes. The UNS N06625 alloy Tubing material is produced in 2 grades. The Inconel 625 Grade 1 Seamless Tubing is furnished in an annealed condition. On the other hand, Inconel 625 Grade 2 Round Tubing, as directed by the ASTM B444 specification is to be furnished in a solution annealed condition. Both grade 1 and Alloy 625 Grade 2 Exhaust Tubing need to strictly adhere to the chemical composition requirements of the said specification. Moreover, the Alloy 625 Grade 1 Welded Tubing is to undergo tests such as the tensile test while conforming to the required room temperature tensile properties. The properties which are to be confirmed by the Sb 444 UNS N06625 Inconel 625 Exhaust Tubing include its tensile strength and yield strength.

In addition, the ASTM B444 UNS N06625 Grade 1 Tube must also conform to the elongation properties. Although these will depend on factors such as the heat treatment used on the UNS N06625 Grade 2 Tubing including small diameter and light-walled 2.4856 Inconel Tubing.

Alloy 825 • UNS N08825

Alloy 825 is an austenitic nickel-iron-chromium alloy also defined by additions of molybdenum, copper and titanium. It was developed to provide exceptional resistance to numerous corrosive environments, both oxidizing and reducing. With a nickel content range between 38%–46%, this grade exhibits pronounced resistance to stress corrosion cracking (SCC) induced by chlorides and alkalis. The chromium and molybdenum content also provides good pitting resistance in all environments except strongly oxidizing chloride solutions. Utilized as an effective material in a wide variety of process environments, alloy 825 maintains good mechanical properties from cryogenic temperatures up to 1,000° F.

Alloy 400 • UNS N04400

Alloy 400 is a nickel-copper alloy exhibiting excellent corrosion resistance in seawater, marine atmospheres, organic acids, and other aggressive media. Alloy 400 exhibits outstanding corrosion resistance, high strength, and toughness over a wide range of temperatures. It is a solid solution strengthened alloy with a nominal chemical composition of 66% nickel, 31% copper, and additions of iron and manganese. It is referred to by the tradename Monel® 400 and the universal designation UNS N04400.

Typical Applications

Condensers

Oil and gas well equipment

Hydraulic systems

Chemical injection lines

Chemical process equipment and vessels

Downhole control lines

Control and instrumentation

Acid Production

Nuclear fuel processing